What is GRP?

If you aren’t familiar with the term ‘glass reinforced plastic,’ you’re probably scratching your head and wondering, “What is GRP?” There’s a good chance you’ve heard its more common name, fibreglass, although it’s also known as composite plastic or fibre reinforced plastic (FRP). GRP behaves in different ways compared to conventional thermoplastics, making it a popular choice for a wide range of applications in many industries.

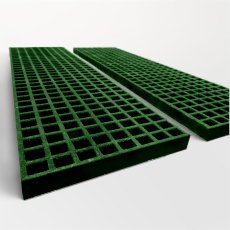

GRP explained

The basic answer to the question, “What is GRP” is that it’s a combination of glass fibre and plastic or polymer. Among its desirable properties are its high strength to weight ratio and superb durability, as well as being electrically non-conductive, lightweight, non-corroding, and radar and radio wave transparent.

What is GRP made of?

GRP products such as GRP profiles are made from glass fibre reinforced polymers, most commonly with a polyester or vinyl ester thermoset resin matrix, and glass fibres.