Do you need Black Rounds, Flats, Squares, or other expertly designed and crafted Re-Rolled Products? You’re sure to find what you’re looking for at BM Steel. Suitable for all applications from construction to manufacturing, our superior Re-Rolled Steel products are durable, affordable, and quality-assured.

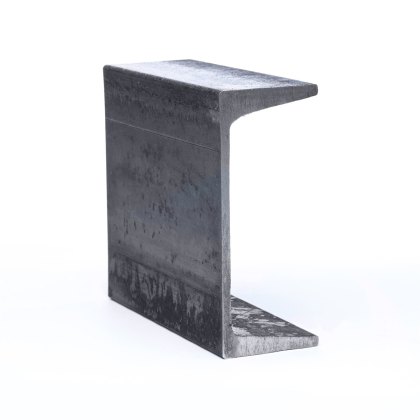

Our Re-Rolled Products range includes Black Rounds, Convex, Black Squares, Black Flats, Angles – Equal, Angles – Unequal, Tapered Flange Channels, and T-Sections. When you choose our products, you choose top-grade steel, reliable strength, and enhanced durability. In addition to enjoying the convenience of ordering premium Re-Rolled Products online, you also get the benefits of fast delivery, great prices, and unbeatable customer service.

Choose from our extensive range of T-Sections, Black Rounds, and other Re-Rolled Products or contact our friendly team about your bespoke requirements today.