BM Steel’s GRP Anti-Slip Range provides a dependable way to reduce slips and falls in high-risk working environments. Manufactured from Glass-Reinforced Polymer (GRP), these products are engineered for long-term durability in areas exposed to heavy use, moisture, or surface contaminants.

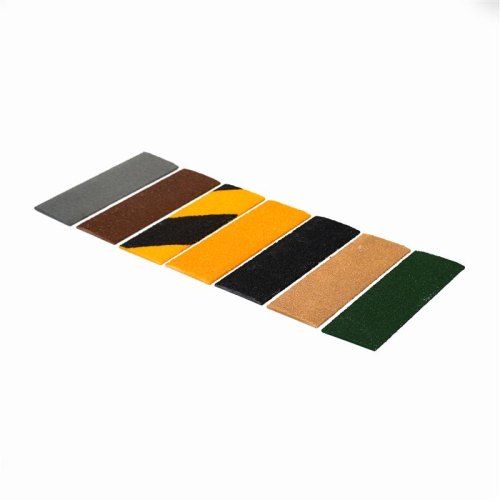

Available as sheets, stair treads and walkway covers, each product delivers a consistently high level of traction where reliable footing is essential.

The combination of fibreglass reinforcement and a gritted surface layer produces a material that is tough, lightweight, and resistant to corrosion.

GRP remains stable under temperature changes and contact with chemicals, making it a safer and longer-lasting alternative to steel, timber, or painted concrete.

Keep the rest of the text hidden behind the "read more" button. Use the same logic for next category pages.

Key Advantages

- Slip-resistant finish: Quartz-gritted surface maintains grip even when wet or oily

- Corrosion-proof: Performs well where metal or wood would degrade over time

- Low weight, high strength: Easy to handle and fit without heavy lifting gear

- Non-conductive: Suitable for electrical or chemically sensitive areas

- Minimal upkeep: No need for repainting or surface sealing

- Extended lifespan: Retains performance in continuous service with minimal wear

These benefits make GRP an ideal choice for busy workspaces and access routes that require safe, stable walking surfaces every day.

Typical Applications

- Access platforms and catwalks

- Factory and warehouse floors

- Service ramps and loading bays

- Stairways, landings, and gantries

- Jetties, maintenance areas, and utilities sites

Each product in the GRP range is designed to improve grip underfoot and protect staff, visitors, and contractors working in exposed or high-traffic areas.