Galvanising

About Galvanising

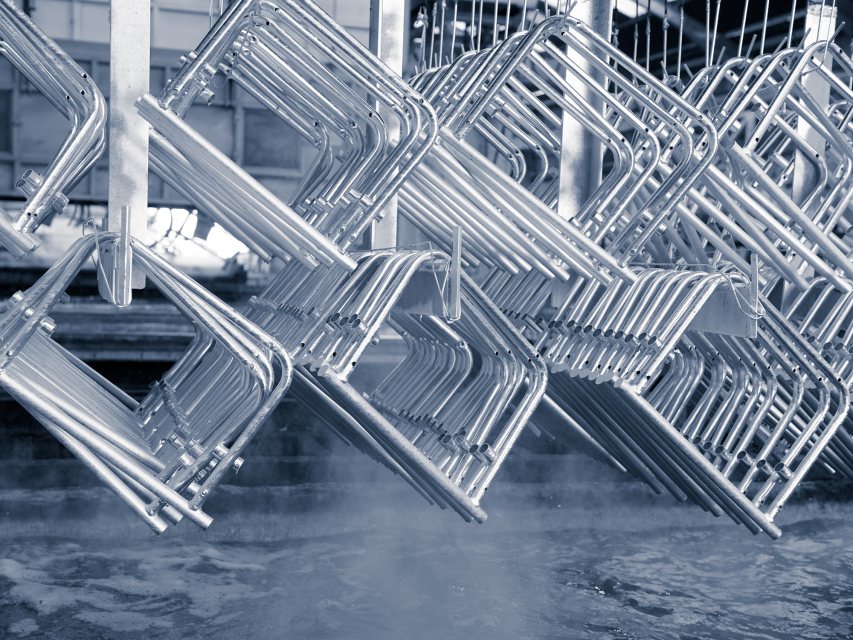

At BM Steel, we provide galvanising solutions that utilise the proven hot dip galvanising process, in which steel is immersed in molten zinc at approximately 450°C to create a tough, metallurgically bonded coating that offers outstanding corrosion resistance and long-term durability. This process ensures complete protection — including edges, corners and internal surfaces — delivering maintenance-free performance that can exceed 70 years, depending on environmental conditions.

As one of the most sustainable and cost-effective steel protection methods available, hot dip galvanising minimises waste by reusing excess zinc and consistently provides the lowest lifetime cost compared with alternative coatings.

Enquire Today