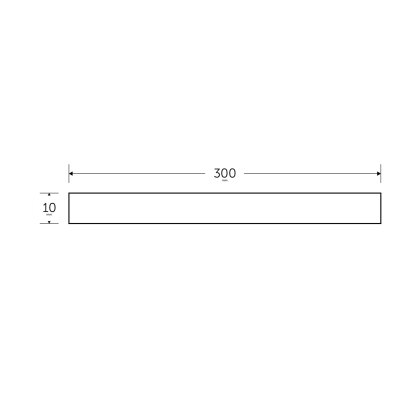

300 x 90 x 41KG Parallel Flange Channels - BSEN10025-2 S275JR

Save 5% on the BM Steel App

The BM Steel App is here to make your shopping experience even better!

This month we are offering BM Steel App users an exclusive 5% off your entire purchase. The discount will be added automatically at checkout.

Download the app today

*Not Including Tools & Workwear.

*Not Including Ecoscape products.

LHPFC-300-90-41-S355

![]() Available

Available

Bulk discounts available:

Buy 6 or more metres at £74.52 per metre

Product Specifications

Product Description

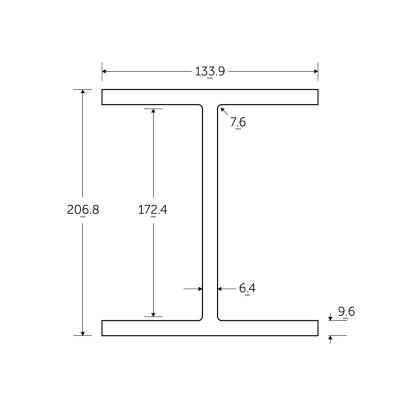

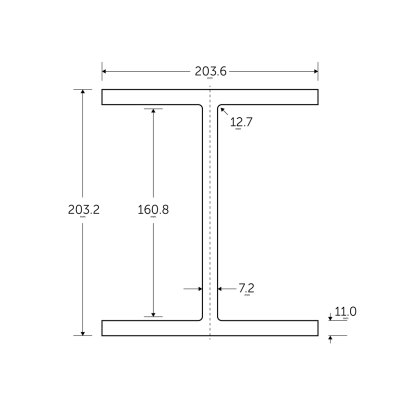

The 300 x 90 x 41KG Parallel Flange Channel - BSEN10025-2 S275JR is a heavy-duty structural steel profile designed for demanding load-bearing applications. Made from S275JR grade mild steel and manufactured in line with BS EN 10025-2 standards, this PFC profile offers a consistent cross-section and excellent strength-to-weight ratio for structural and architectural steelwork.

With a 300mm depth, 90mm flange width, and a unit mass of 41kg per metre, this channel is engineered for serious support work. It performs well in both horizontal and vertical load-bearing setups and is widely used in steel framing, platform edge support, gantries, industrial flooring systems, and large-scale balustrade structures. The parallel flanges provide uniformity, simplify fabrication, and support bolted or welded connections with standard fittings—including balustrade end caps.

This profile is supplied in standard stock lengths or can be cut to size upon request. It can also be primed, painted, or galvanised for corrosion resistance.

The 300 x 90 x 41KG Parallel Flange Channel is suited for use in:

- Structural steel framing for commercial and industrial buildings

- Secondary steelwork in portal frame construction

- Load-bearing gantries and support brackets

- Elevated platforms and walkways with grating systems

- Heavy-duty racking systems and machinery support frames

- Steel staircases, especially where flanges are needed to support treads or landings

- Architectural and structural balustrades, including systems requiring integrated end caps

- Retaining wall structures and beam-and-post systems

- Lift shaft reinforcement or shaft wall framing

- Trailer bed construction and large vehicle chassis

FAQ

What welding considerations apply to this PFC when connecting it to structural columns?

Ensure the weld sequence accounts for distortion due to the profile?s mass. For fillet welds at the flange-web interface, use controlled heat input and backstep welding to reduce shrinkage. Preheat may be required depending on thickness and joint design.

Is this section suitable for edge protection in precast floor support systems?

Yes. The parallel flange geometry provides consistent bearing and easy fixing to adjacent slabs or steelwork. Use appropriate shear connectors or mechanical fixings when integrating with concrete elements.

How does the mass per metre affect fixing and installation planning?

At 41kg per metre, this channel requires mechanical lifting for anything over short spans. Consider lifting beam certification and proper edge restraint during installation to prevent rotation or deflection.

What corrosion protection options are recommended for coastal or industrial sites?

Hot-dip galvanising is preferred for long-term protection in marine or high-sulphur environments. Alternatively, a zinc-rich primer followed by a polyurethane topcoat can provide effective layered defence in milder settings.

Can I use standard balustrade end caps with this profile?

Yes. The regular parallel flange design is compatible with off-the-shelf balustrade end caps. For architectural use, ensure any aesthetic elements are aligned with the channel?s face or incorporate shims where needed.

check delivery cost

check delivery cost login to save

login to save ask a question

ask a question