Open Steel Utility Flooring 6000mm x 1000mm (25 x 5 x 41 x 100) - Self Colour

Save 5% on the BM Steel App

The BM Steel App is here to make your shopping experience even better!

This month we are offering BM Steel App users an exclusive 5% off your entire purchase. The discount will be added automatically at checkout.

Download the app today

*Not Including Tools & Workwear.

*Not Including Ecoscape products.

MFOMP-25-5-41/100-PLA-SC

![]() Available

Available

Product Specifications

Product Description

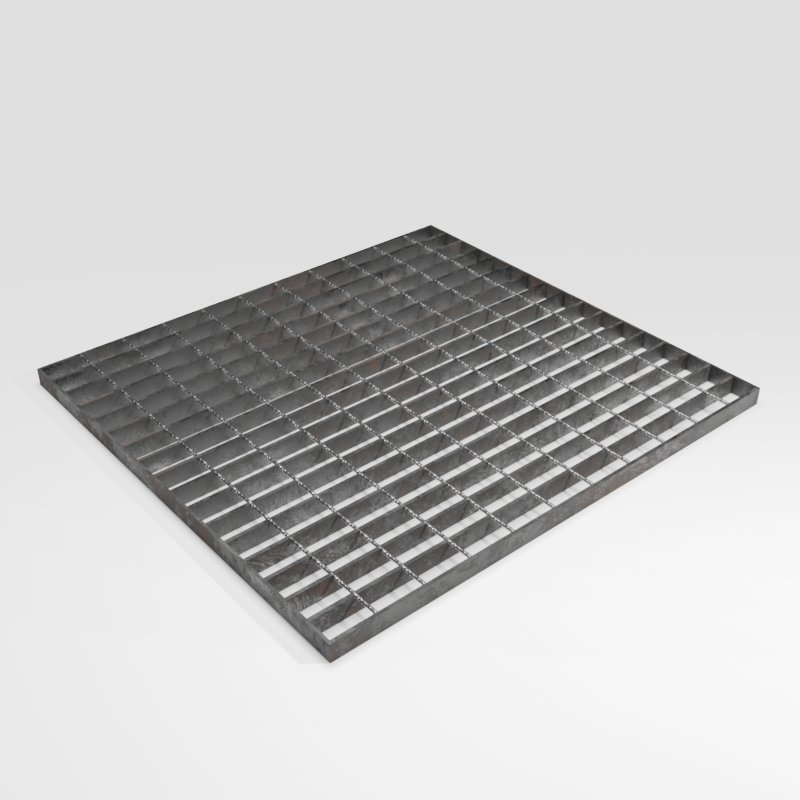

The Open Steel Utility Flooring 6000mm x 1000mm (25 x 5 x 41 x 100) – Self Colour panel is a heavy-duty solution for creating safe and durable access across industrial and commercial sites. Manufactured from high-quality steel flooring, it combines strength and long service life with straightforward installation.

Each panel is constructed with 6 mm square twisted transverse bars resistance-welded to the top of the load-bearing bars. This keeps the main bars upright at consistent intervals, ensuring structural integrity while allowing dirt, liquids, and debris to pass through. It is ideal for open steel flooring in demanding environments.

The metal mesh floor design is particularly useful where drainage and slip resistance are essential, such as over shallow trenches, around water-treatment channels, or on solid ground to protect walkways from contamination.

Key Features

- Robust steel flooring panel measuring 6000 mm x 1000 mm

- Open-mesh pattern (25 x 5 x 41 x 100) promotes drainage and reduces debris build-up

- Self colour finish ready for on-site galvanising, painting or other coatings if required

- Twisted 6 mm transverse bars keep load-bearing bars firmly in position

- Suitable for heavy industrial loads and high-traffic applications

Typical Uses

- Open steel flooring for walkways, platforms and mezzanine decks

- Metal mesh floor coverings above water channels or service trenches

- Heavy-duty flooring in factories, treatment plants and processing facilities

FAQ

How should the substrate be prepared for installing open steel utility flooring?

Ensure all supporting steelwork or concrete is level and capable of carrying the design load. Accurately position fixing clips or welding points to avoid distortion during installation.

What protective coatings are recommended for the self colour finish?

The self colour surface can be hot-dip galvanised, painted or powder coated on site. Protective treatment is advised for outdoor or corrosive environments to extend service life.

Does the 6 mm twisted transverse bar contribute to the load capacity?

The transverse bar primarily holds the main bearing bars upright and evenly spaced. The load-carrying capacity is provided mainly by the primary load bars.

How is drainage handled in wet or contaminated areas?

The 41 x 100 open mesh design allows water, dirt and waste to fall through, reducing slip hazards and simplifying cleaning, making it ideal for treatment plants or outdoor walkways.

Can the panels be cut to size on site?

Yes. Panels can be trimmed using appropriate cutting tools. All cut edges should be treated or coated to maintain corrosion resistance and structural safety.

What fixings are recommended for secure installation?

Use galvanised clips, saddle clamps or welds as specified by the structural engineer. Properly anchored fixings ensure long-term stability under heavy foot or equipment traffic.

download pdf files

download pdf files check delivery cost

check delivery cost login to save

login to save ask a question

ask a question